Boring Mills

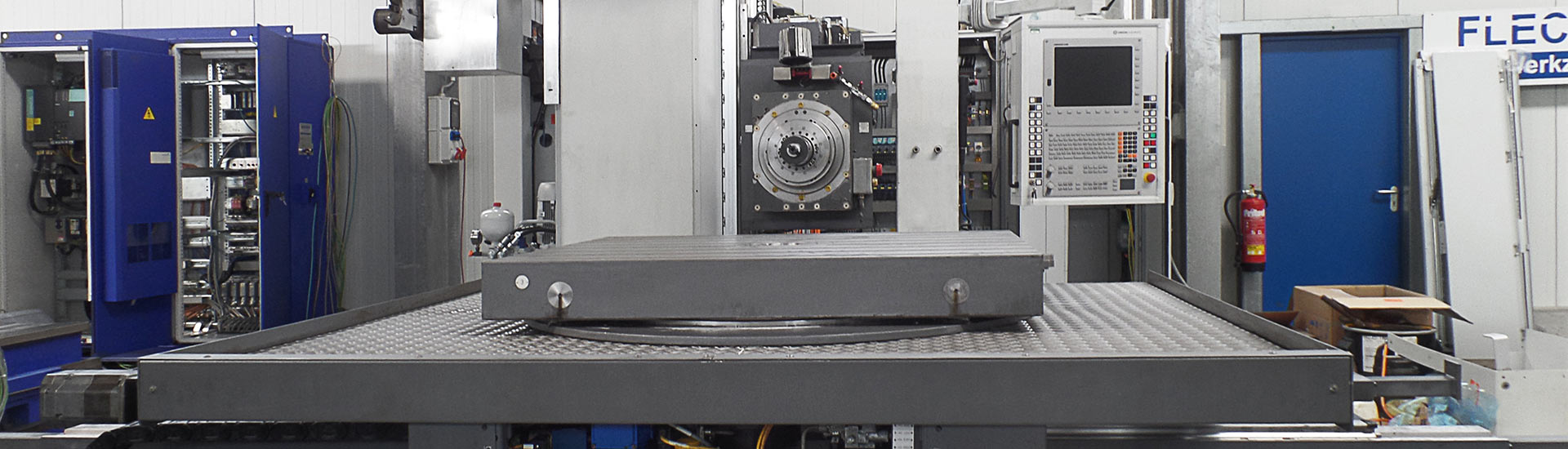

CNC-Horizontal Floor Type Boring and Milling Machine PAMA SPEEDRAM 2

SINUMERIK 840 C

Built 2002

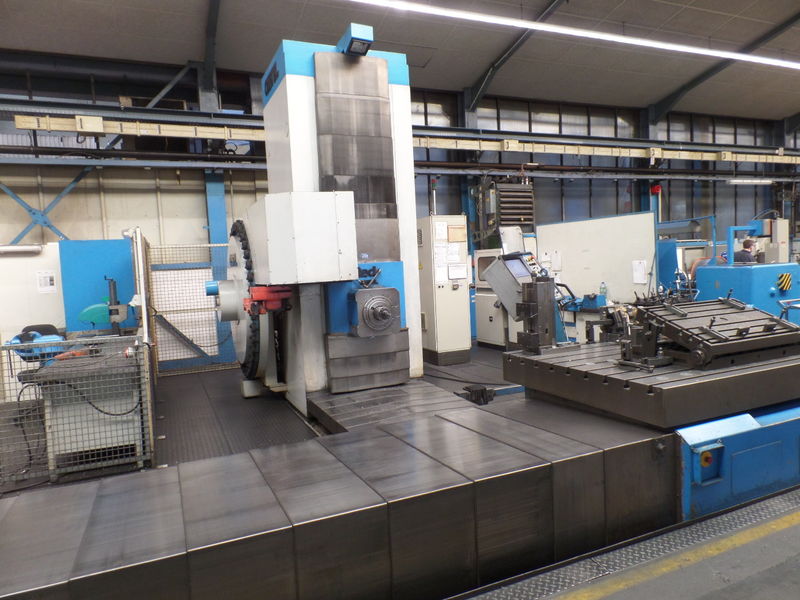

CNC-Horizontal Boring and Milling Machine FPT CASTEL RED

SINUMERIK 840 D Solution Line

Built 2012

High-quality used boring mills from Fleckenstein Machine Tools

Precision for large components

Boring mills are the ideal choice when it comes to the complex machining of large and heavy components. These versatile machines, often referred to as horizontal boring and milling machines, offer impressive flexibility in various sizes and configurations, depending on the specific requirements of the application.

The main features of a boring mill are its robust construction, which enables high cutting speeds and precise machining. These characteristics make the boring mill an indispensable tool in numerous fields. Whether in the automotive industry or in the production of machine components – wherever the highest precision and quality are required, the boring mill is used.

Modern CNC boring mills are also equipped with automatic tool changers and indexable clamping tables, further increasing flexibility and efficiency.

Efficiency through easy tool changes

The strength of modern boring mills lies in their impressive flexibility and efficiency, making them indispensable tools in industry. These machines are specifically designed to machine a wide variety of components and perform numerous operations in the highest precision level. Instead of laboriously transporting workpieces from machine to machine, innovative technology allows users to quickly remove and install tools. This enables multiple operations, such as drilling, milling, and even turning, to be completed in a single pass. This not only saves valuable time but also significantly increases productivity. With a headstock that integrates a work spindle, also known as a quill, which moves in the direction of travel, these boring mills can carry high loads in the table and are ideally suited for machining massive components.

What types of boring mills are there?

There are a variety of boring mills that differ in their design and application:

1. Cross or T-type boring mills:

These have two horizontal beds connected in a T-shape. A rotary table moves on the transverse bed, while the column with the headstock is positioned on the longitudinal bed. This boring mill facilitates handling, especially with larger workpieces. These boring mills can also be automated in-house using tool changers, allowing for machining during setup times. Because the table bed is directly connected to the base, heavier workpieces can typically be handled than with the following variant:

2. Table-type boring mills:

These have a movable rotary table mounted on a horizontal base frame, also known as a cross table. The column with the headstock, which is often fixed, can be moved vertically, allowing workpieces to be machined on the table. These machines are ideal for use in confined spaces. They offer a good combination of mobility and stability.

3. Floor Boring Mills:

These machines are ideal for machining very large workpieces. They are usually equipped with large floor plate fixed to the base, while the column and headstock move on the lateral side a transverse bed. These type of machines are often equipped with additional components such as rotary tables or head-changing stations.

4. CNC Boring Mills:

This designation refers less to the construction than to the control technology used. Each of the types mentioned above can be CNC-controlled. Computer-controlled machines combine the highest precision with automation. They are perfectly suited for industrial production and enable complex machining operations with minimal effort.

Why buy used boring mills?

Acquiring used boring mills offers numerous advantages that can be crucial for companies of all sizes. First and foremost is the price: Used machines are generally significantly cheaper than their new counterparts, without compromising quality or performance. Another advantage is immediate availability. While purchasing new machines often involves long delivery times, with used boring mills you can act quickly and increase your production capacity in the short term.

Furthermore, many used boring mills already incorporate proven technologies and features that have demonstrated their reliability in practical applications. You can often rely on high-quality machines that have been well-maintained and will remain efficient for many years to come. With careful selection and a thorough inspection of the machine's condition, you can ensure you receive a high-quality product. Last but not least, purchasing used machinery contributes to sustainability. By utilizing existing equipment, you reduce the need for new resources and thus contribute to environmental protection.

High-Quality Used Boring Mills for Trade and Industry

At Fleckenstein Machine Tools, we present a carefully curated selection of high-quality used boring mills, specifically designed for tradespeople and industrial companies. Every single boring mill in our inventory is thoroughly inspected and, if necessary, refurbished to ensure it meets the highest standards of industrial application. Our manufacturers include renowned names such as UNION, TOS, SCHARMANN and FPT, all of whom have earned an excellent reputation in the used machinery sector. If the right boring mill is not currently available, please contact us or subscribe to our newsletter. We are constantly receiving new, unlisted machines.

We would be happy to review your requirements and assist you in finding the ideal machine.