Grinding Machines

Universal cylindrical grinding machine DANOBAT R3-4000-S5

SiNUMERIK 840 D

Built Retrofit 2024

CNC - Internal Cylindrical (ID) Grinder ROWEIG SI8-2x500

SIEMENS Sinumerik 802D solution line

Built 2014

Precision -Flat- and Profile Grinder ABA POWERLINE 1006 CNC

SINUMERIK 840 D

Built Retrofit 2024

Upgrade Your Production – with used grinding machines from Fleckenstein.

What is a grinding machine?

A grinding machine is a machine tool that processes workpieces with high precision by removing material from the surface. This is done using rotating grinding wheels, belts, or discs coated with abrasive grains.

These tiny abrasive grains can be made of various, but very hard, materials. In industry, ceramics such as silicon carbide or cubic boron nitride (CBN) are often embedded in a bonding agent and mounted on a base, which in turn sits on the rotating grinding spindle.

The use of diamond-tipped grinding wheels is also possible and common practice, often in dressing technology for dimensional correction of the installed grinding wheels directly on the machine.

Grinding is generally a finishing process. It produces smooth, precise surfaces – often the final step in metalworking after heat treatment, whether in toolmaking or the production of precision parts.

Grinding machines are used wherever micrometer-level accuracy is required. Depending on the application, various types are distinguished in machine tool manufacturing:

- Surface grinding machines for flat surfaces,

- Cylindrical grinding machines for cylindrical workpieces,

- Tool grinding machines for cutting tools,

- Gear grinding machines for the finishing of a wide variety of gear geometries.

The History of the Grinding Machine

The history of the grinding machine stretches far back – and shows how craftsmanship and industry have continuously evolved. Originally, materials were processed by hand using grinding stones or sandpaper. This laborious process primarily served to smooth surfaces or break edges.

With the onset of industrialization in the 19th century, this changed. The increasing demand for precisely manufactured metal parts led to the development of the first mechanical grinding machines. Powered by waterwheels, steam engines, or later electric motors, they could process workpieces significantly faster and more accurately than by hand.

Over time, specialized machines for different applications were developed – such as gear grinding machines, cylindrical grinding machines, and tool grinding machines. Each of these was specifically further developed to meet the increasing demands for dimensional accuracy, surface quality, and productivity.

Today, modern CNC grinding machines are high-tech devices that operate precisely, automatically, and energy-efficiently. Nevertheless, their basic principle is still based on the same idea as before: material is removed in a controlled manner to achieve a perfect result.

When should you use which grinding machine?

Depending on the workpiece, material, and desired surface quality, a different grinding machine is used. Grinding is not just grinding – each process has its own strengths. Here's an overview of when which grinding machine is the right choice:

Surface grinding machines

These machines are used when flat surfaces need to be machined precisely – for example, on tool plates, mold inserts, or machine components. Ideal for high dimensional and geometric accuracy.

Cylindrical grinding machines

When machining rotationally symmetrical workpieces such as shafts, flanges or rollers, the cylindrical grinding machine is the first choice. It enables the precise machining of the inner and outer surfaces of cylindrical parts.

Tool grinding machines

These are used to sharpen or regrind cutting tools such as milling cutters, drills, or turning tools. They are indispensable, especially in series production, to ensure consistent cutting quality.

Gear grinding machines

These machines are further subdivided according to their grinding operation: profile gear grinding machines or continuous gear grinding machines, or according to the workpieces being machined: cylindrical gear grinding machines or bevel gear grinding machines.

CNC grinding machines

Where the highest precision is required, CNC-controlled grinding machines are used. They enable automated, repeatable processes and are particularly economical in series production. CNC grinding machines can be found in all the aforementioned categories.

Used Grinding Machines from Fleckenstein Machine Tools – Precise, Robust & Economical

Precision is paramount in industrial manufacturing – and that's exactly what our used grinding machines deliver. Whether surface grinder, cylindrical grinder, tool grinder, or belt grinder: In this category, you'll find high-quality machines from renowned manufacturers that have been reliably used and, after technical inspection, are ready for the next production line.

With a used grinding machine from Fleckenstein, you benefit twice over:

You get proven industrial quality at a significantly lower price and secure short delivery times. Many machines are available immediately and are perfect for companies that want to expand their capacities or need replacement machines – without having to wait months for new equipment.

Our selection of used grinding machines covers virtually all metalworking requirements – from precise surface finishing to the final machining of complex workpieces. Every machine is tested before sale to ensure performance, accuracy, and repeatability.

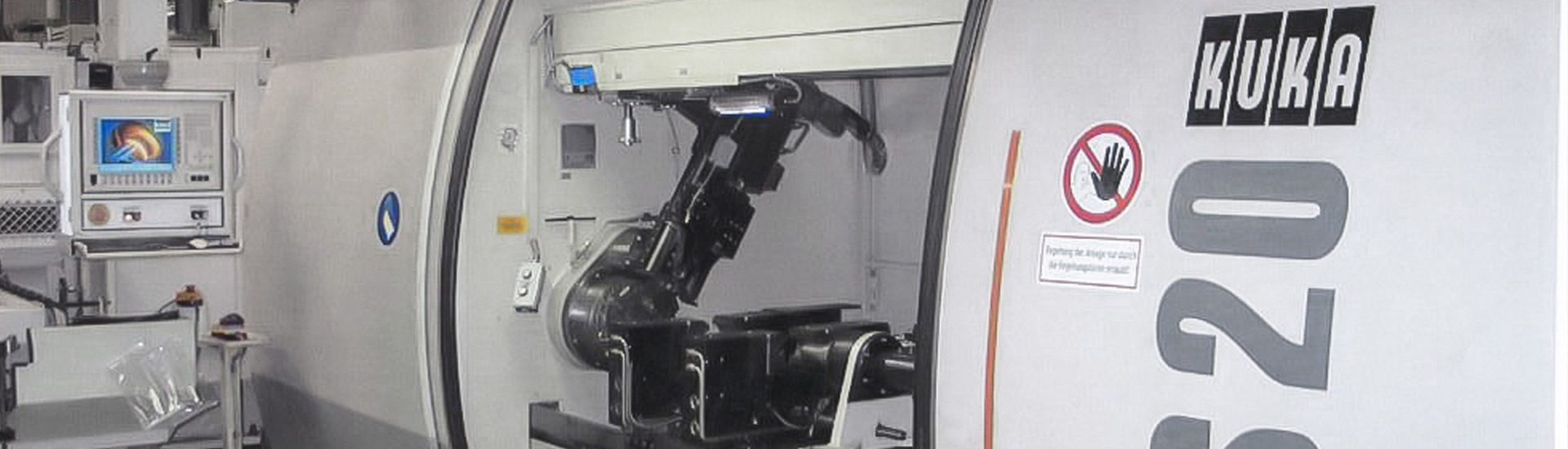

Popular brands in our product range:

- Kapp Niles

- Gleason Pfauter

- Höfler

- Reishauer

- Kellenberger

- Schaudt Mikrosa

- Danobat

- Elb Schliff

- Blohm

- ABA

- Mägerle

- and many more.

And if you don't currently have what you're looking for:

Please contact us directly or subscribe to our newsletter. We are constantly receiving new, unpublished machines. We would be happy to review your requirements and assist you in finding the ideal machine.