Lathes

Used lathes for precision manufacturing – quality from Fleckenstein machine tools

With the advancing industrial revolution in the 19th century, the first machine tools also found their way into factory halls. The lathe, as a further development of the lathe already long established in woodworking, made a decisive contribution to this development. Many machine components could only be manufactured economically in significant quantities through turning, thus in turn reducing the costs of textile or steam engines. The importance of the machine tool as the basis and cornerstone of industrial production technology remains to this day.

Precision in Motion

Lathes are specialized machine tools used in machining to produce rotationally symmetrical components. They enable the precise manufacturing of both simple cylindrical or flat surfaces perpendicular to the axis of rotation, as well as more complex geometries such as conical and spherical surfaces. Unlike other machining processes, in turning the workpiece rotates, generating the cutting motion, while the tool is rigidly clamped and provides the feed motion. The tool slide moves both longitudinally and transversely to the workpiece's axis of rotation, removing material from the surface in the form of chips. This machining can be performed both conventionally and using CNC (computer-aided machining), ensuring high precision and repeatability.

How is a lathe constructed?

The construction of a lathe is well-designed and functional to enable precise machining. The stable frame and the machine bed, made of vibration-damping steel or cast iron, form the foundation upon which all other components rest. The tool slide, tailstock, and steady rest are mounted on the machine bed. The workpiece is held in the headstock by the work spindle and rotates there at an adjustable speed, controlled by the gearbox. As the workpiece rotates, the tool slide guides the turning tool along it, removing material bit by bit until the desired shape is achieved. Particularly long workpieces are securely supported by the tailstock with its center point, while the steady rest effectively prevents vibration or deflection of thin and long turned parts. This well-designed construction ensures precise and efficient machining results.

What types of lathes are there?

The development of lathes has continuously adapted to the individual requirements of the market over time. In today's manufacturing industry, lathes find diverse applications, as turned components are used wherever something rotates or moves. These state-of-the-art turning systems are often modular in design and can be flexibly adapted to the specific needs of the users.

Lead screw and feed screw lathes

Lead screw and feed screw lathes are manually operated horizontal lathes with a left-hand spindle and a right-hand tailstock. They form the technical basis of universal lathes and can be expanded modularly to efficiently perform all common turning processes. Particularly in single-part and small-batch production, they offer an economical solution due to their low planning requirements and high flexibility.

CNC lathes

CNC lathes are computer-controlled systems for the mass production of turned parts, ensuring consistent quality through programmed control. They often feature RC interfaces for direct import of CAD data, as well as additional auxiliary axes and motorized feed axes with linear encoders, which simplifies operation and enables precise processes. Modular expansion stages allow for flexible adaptation to individual production requirements.

Vertical turning lathes

Vertical turning lathes with a horizontal faceplate are used for the production of large turned parts. The workpiece is clamped centrally on the horizontally rotating faceplate and machined with up to three independent turning tools, which reduces machining time and enables economical production of large and long turned parts.

Flatbed Lathes

Flatbed lathes are center-center lathes with a horizontal machine bed and automatic drives. Their rigid construction allows them to withstand high machining forces and precisely machine heavy turned parts. Due to their robust design, they are relatively expensive, which is why modular designs are often used.

Front-Mounted Lathes

Front-mounted lathes are primarily used for manufacturing turned parts without tailstock support. Their transverse or vertical machine bed enables a compact design and good accessibility. Typical applications for smaller models include the jewelry and watchmaking industries. Front-mounted lathes for large components such as flanges or rings are also known as headstock lathes.

Efficient Solutions with Used Lathes

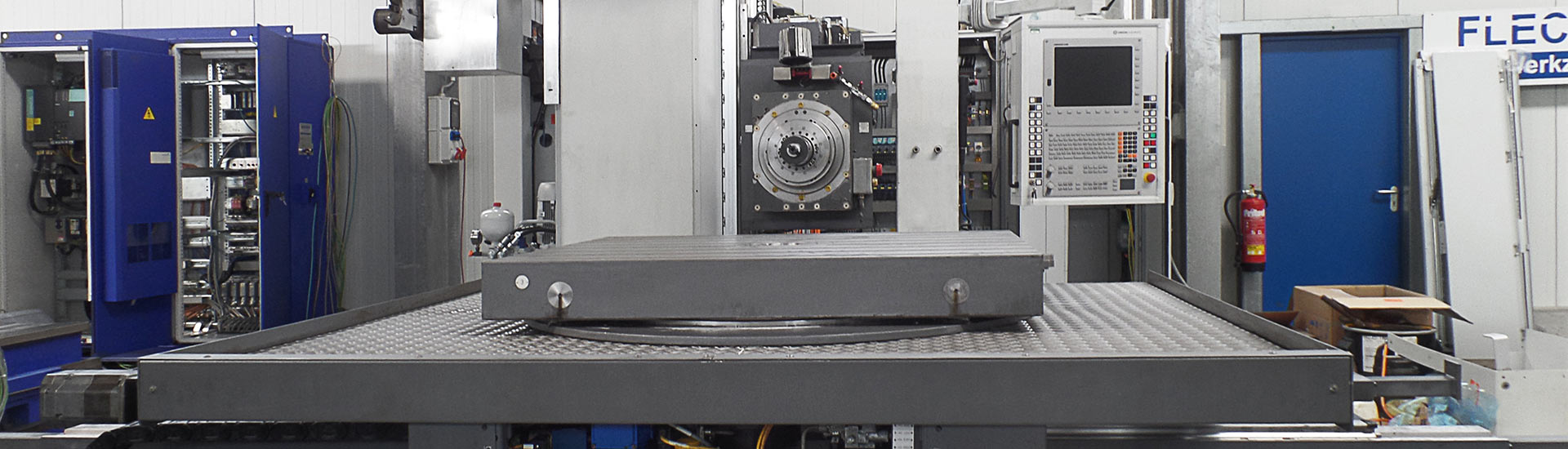

Used lathes from Fleckenstein Werkzeugmaschinen offer you an economical and reliable way to efficiently expand your production capacity. Every machine in our range undergoes a thorough technical inspection to guarantee functionality, precision, and safety at the highest level. Our selection includes both conventional and CNC-controlled lathes, which impress with their rapid availability and flexible adaptability to diverse production requirements. Benefit from attractive prices, short delivery times, and expert advice that helps you sustainably optimize your manufacturing processes without high investment costs.

At Fleckenstein Machine Tools, we also carry used lathes from renowned brands such as DMG Gildemeister, Boehringer, Weiler, and DANOBAT, which are characterized by their durability, precision, and innovative technology, and offer excellent performance even after several years of operation.

If the model you are looking for is not currently available, we invite you to subscribe to our newsletter or visit us again at a later date. Of course, our experienced and knowledgeable staff are always happy to provide you with personalized advice – contact us today to find the ideal solution for your production needs.