The retrofit boring machine that can handle 6t control blocks!

Retrofitting is 50% cheaper. Water hydraulics specialist Tiefenbach has purchased a 20-year-old Union drilling machine. Retrofitter Björn Fleckenstein explains the manufacturing advantages of the TC110 on-site.

from HARALD KLIEBER

Water hydraulics is alive! The systems manufacturer Tiefenbach, based in southern Essen on the Ruhr River, proves this every day.

"Water hydraulics is dead – that's what my father told me when I joined the company in 2006. But over the past 20 years, we've proven with numerous projects that water hydraulics is a serious competitor to oil hydraulics – and not just because of fire protection." Managing Director and product expert Marc Emmaneel points out, above all, the incomparably higher energy efficiency, which means that in large oil hydraulic installations, for example, 28 1,000-liter pumps are required to provide high pressure, whereas water hydraulics can manage with four 1,000-liter pumps.

Using digitalization and automation to combat the shortage of skilled workers "These are huge energy advantages. This factor of seven difference is not unusual, but rather the average.

And for experts: Our systems now decompress from 500 to 0 bar in 0.87 seconds without pressure surges. That's a truly outstanding value – and not just anyone can do that!"

According to Marc Emmaneel, traditional oil systems would only be effective when open-die forging presses have a high number of finishing strokes, when Tiefenbach's otherwise sought-after battery-powered technology reaches one of its few technical limits.

"Water hydraulics are running. It's not without reason that we are investing in our machinery to maintain our high level of vertical integration, which extends right down to the windings and explosion-proof housings of our self-developed electric motors. Furthermore, we plan to use our own resources to counteract the shortage of skilled workers with even more automation and new machining centers from Index and Heller."

“What particularly convinced us was the digitalization of the boring machine with a Heidenhain 530.”.

Dirk Hellwich, Operations Manager

Serious retrofitter with a lot of experience

Operations manager and CNC machine expert Dirk Hellwich describes the challenging planning for the acquisition of the boring machine, which went into operation in 2024 without any problems – especially for machining the oversized hydraulic control blocks weighing up to 6 t – as a huge step towards automation.

"Of course, praise goes to Björn Fleckenstein and his team, who not only provided us with excellent advice but also provided us with help and advice during installation.

I'm just thinking of the existing foundation of the previous machine, which Fleckenstein transformed into CNC-compatible, fundamental support points with a few tricks and a new connection."

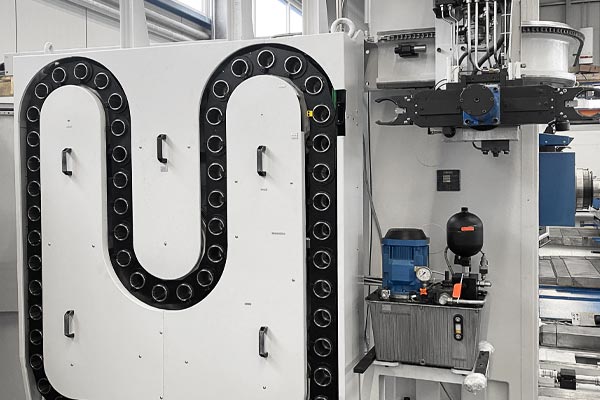

According to Dirk Hellwich, the machine-side adjustment was somewhat more complex: Where previously there was a free flight path for chips and coolant, a total of three chip conveyors were installed, which now allow maximum travel distances in the smallest possible space for the Union boring machine built in 2004. The new TC110 became necessary after the effects of the 2021 Ahr Valley floods reached Tiefenbach via the nearby Ruhr River.

Select controls according to process requirements

"Boring mills really can't swim," Marc Emmaneel recalls. A replacement machine didn't help either. "It's a good thing that, in terms of machine expansion, we'd already noticed Fleckenstein's website and their used machines several times," Dirk Hellwich explains how they made contact.

Everything moved quickly at the on-site appointment in Kleinostheim near Aschaffenburg. "What convinced us most was the digitalization of the boring mill with a Heidenhain 530. That was one of the deciding factors. Not retrofitting with a completely overpowered TNC7, but selecting exactly the right control system for this boring mill. That's all you need for Union's very precise, yet relatively uncomplex processes," emphasizes Dirk Hellwich.

Automation allows multi-shift production

A major advantage is that the 530 is capable of thread milling, thus eliminating the time-consuming tapping, pre-drilling, and the necessary tool changes, including inspection, calibration, presetting, and purchasing. "There's a lot to consider. Control blocks not only cut many threads, but also large ones – up to M72," emphasizes Dirk Hellwich.

„Diese heiklen Prozesse lassen sich nun mit deutlich günstigeren Werkzeugen ganz einfach und vollautomatisch ohne jedes Werkzeugbruchrisiko ausführen“, berichtet Bohrwerk-Experte und Bru- der Frank Hellwich.

Denn das alte Bohrwerk hatte auch keinen Werkzeugwechsler. Jedes Werkzeug musste also von Hand in die Spindel eingesetzt und wieder entnommen werden. Tieflochbohrungen mussten teilweise per Handrad gefinisht werden. „Das neue Bohrwerk macht das alles automatisch – und kann eben auch Gewindefräsen.

Perfekt. Das ist ein riesiger Fortschritt“, freut sich Frank Hellwich, dem nun auch die aufwändigen Reparaturen durch abgebrochene Gewindebohrer an den großen Steuerblöcken erspart bleiben.

Retrofit only with warranty and CE certificate

"Final tapping has truly lost its terror with thread milling. But what's even better is that with the retrofitted boring machine, we can now also move into multi-shift machining." Currently, according to Dirk Hellwich, two-shift spindle utilization is already in preparation. "Of course, Tiefenbach will gain immense spindle capacity in one fell swoop." According to Björn Fleckenstein, the machine is 100% designed for this purpose. All spindles, housings, bearings, and gears were reconditioned during the retrofit. "We purchase any machine we consider interesting—because it's established, particularly stable, or simply very popular in the market—and work on any backlog of maintenance as needed.

The customer essentially receives a new machine from Fleckenstein Werkzeugmaschinen—with CE and the corresponding warranty," says Björn Fleckenstein, explaining his retrofit and used machine business.

Subsidies for energy-saving machines

Ten employees in Kleinostheim near Aschaffenburg handle inquiries: Fleckenstein buys used machines, modernizes them, retrofits them, advises on them, and sells them. "Of course, we also fulfill special requests, paint the machines in the desired color—but we're also increasingly automating and digitizing them. And we're actually seeing a significant increase in buyer interest at the moment, which may also be due to the subsidies still available for particularly energy-efficient machines," says Björn Fleckenstein, pointing out another very good reason to consider purchasing a retrofitted machine.

„Energy savings can quickly turn the 2 before the decimal point into a 1 when calculating interest.”

Marc Emmaneel, Managing Director Tiefenbach Wasserhydraulik

Maximum points with energy savings

For the drilling machine alone, Tiefenbach was able to claim CO2 savings of around 15 to 20 tons compared to a new machine. Marc Emmaneel explains that it is therefore equally interesting to know the degree of digitalization of its machines and processes so that these insights can be incorporated into the machine financing. "You can really score the most points with the energy savings. This quickly turns the 2 before the decimal point into a 1 when calculating interest," Marc Emmaneel emphasizes the highly lucrative savings potential.

State-of-the-art digital motors are super-precise and save energy

From a technical perspective, digitalization has made significant strides in manufacturing at both the boring mill and Tiefenbach. "All motors have been refurbished or replaced and are now state-of-the-art. We only use digital motors with minimal power consumption, maximum precision, and efficiency. Ditto the linear axes. Everything is now state-of-the-art!"

Tool changer and magazine are the productivity drivers

Björn Fleckenstein doesn't recommend larger or more powerful motors. While tuning would be feasible, it wouldn't make sense because the machine's dimensions and design aren't designed for greater acceleration. "The designers had already considered a lot of things when developing the machines in the 2000s. Even significantly more powerful spindles are usually not optimal. We particularly recommend reconditioning the headstocks and quills, and especially upgrading the Union boring machines with tool changers and a tool magazine – these are the real productivity boosters for 24/7 operations!"

Save space and investment with retrofit machines

Overall, Marc Emmaneel sees the retrofit machines as ideal, especially for the batch-size-one production of heavy control blocks. "The cost-benefit ratio of 50% less investment and at least 30% more efficient processes is simply not achievable with new machines – especially not with control blocks."

And Dirk Hellwich sees the matching control systems as a major advantage. Furthermore, these boring mills would fit perfectly into Tiefenbach's tight production space. "Our boring mill is approximately 3 x 4 meters. Comparable boring mills that can process control blocks weighing up to 6 tons require at least twice to four times the space – not to mention the investment."

We're probably talking about millions that we were able to save with the Fleckenstein machine," says Dirk Hellwich, highlighting the advantages of Fleckenstein's retrofit machines.

You can download the article here.